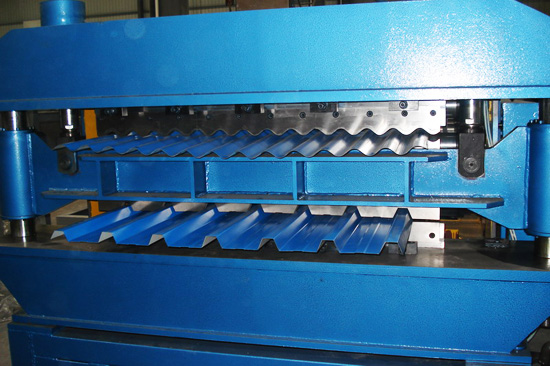

PROFILE

.png)

-EQUIPMENT OF MACHINE

1. Machine’s Components

|

1 |

5tons manual uncoiler with new brake design |

1set |

|

2 |

Coil sheet guiding and adjust department |

1set |

|

3 |

Main roll forming system |

1set |

|

4 |

Hydraulic cutting department |

1set |

|

5 |

Hydraulic station |

1set |

|

6 |

PLC control table |

1set |

|

7 |

Final product runout table |

1set |

2. Technician parameter

|

No. |

item |

Parameter(all is subject to our final design) |

|

|

1

|

Suitable raw material |

Type |

Common galvanized steel strip |

|

Yield strength |

235MPa~345Mpa |

||

|

Thickness(mm) |

0.4mm~0.7mm |

||

|

width(mm) |

According to final design |

||

|

2 |

Manual uncoiler’s capacity |

Max.5tons |

|

|

3 |

Forming speed(m/min) |

About 14~20m/min |

|

|

4 |

Main motor power(KW) |

5.5kw |

|

|

5 |

Hydraulic power(KW) |

3kw |

|

|

6 |

Forming roller groups |

Around 18-19 groups(according to final design) |

|

|

7 |

Raw material of forming roller |

High quality No.45 steel |

|

|

8 |

Raw material of cutting blade |

Cr12mould steel with quenched treatment |

|

|

9 |

controlling system |

Mitsubishi PLC& converter |

|

|

10 |

Suitable industrial voltage |

According to your special requirement |

|

|

11 |

Machine weight |

About 9 tons(according to final design) |

|

- MACHINE WORKING FLOW

.png)

picture